WF SERIES (WARM HOT FORGING PRESS)

MECHANICAL PRESS

FEATURES

- Ultra rigid frame

- High rigidity of forged alloy steel eccentric shaft

- Slide eight point gib ensures forging precision

- WF1-G models are all equipped with transmission gears, which are suitable for forging aluminum alloy, work piece.

- Slide CAE structural analysis ensures high rigidity.

SPECIFICATIONS

| MODEL | WF1 -400 | WF1 -600 | WF2 -800 | WF2 -1000 | WF2 -1600 | WF2 -2000 | WF2 -3200 |

|---|

| F | F | F | G | F | G | F | G | G | G |

| Capacity | Tons | 400 | 600 | 800 | 1000 | 1600 | 2000 | 3200 |

| Stroke Length | mm | 175 | 200 | 250 | 300 | 330 | 330 | 360 |

| Stroke Per Minute | SPM | 100 | 85 | 75 | 60 | 70 | 55 | 70 | 50 | 48 | 42 |

| Slide Adjustment | mm | ۱۰ |

| Die Height(S.D.A.U) | mm | 505 | 550 | 650 | 700 | 800 | 900 | 1200 |

| Bolster Area (L.R×F.B) | mm | 770×840 | 880×880 | 900×800 | 1000×1050 | 1250×1150 | 1450×1400 | 1750×1600 |

| Bolster Thickness | mm | 120 | 120 | 160 | 160 | 200 | 300 | 300 |

| Slide Area (LR×FB) | mm | 595×555 | 695×635 | 800×750 | 900×880 | 950×900 | 1300×1200 | 1550×1450 |

| Main Motor | kw×p | 37×6p | 45×6p | 55×6p | 45×6p | 75×6p | 55×6p | 110×6p | 75×6p | 90×6p | 132×6p |

| Slide Knock-out Device | Ton/mm | 4/20 | 6/20 | 8/30 | 10/35 | 16/40 | 20/45 | 32/45 |

| Bed Knock-out Device | Ton/mm | 8/40 | 10/40 | 15/50 | 20/60 | 30/65 | 40/70 | 65/70 |

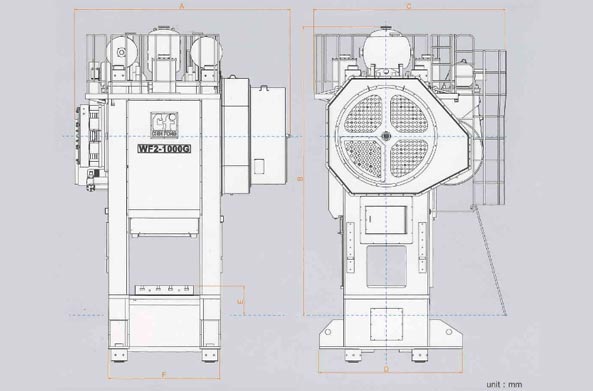

DIMENSIONS

| MODEL | WF2 -800 | WF2 -1000 | WF2 -1600 | WF2 -2000 | WF2 -3200 |

|---|

| TYPE | G | G | G | G | G |

| A | 4100 | 4350 | 4810 | 5400 | 6100 |

| B | 5300 | 5500 | 6280 | 6530 | 7505 |

| C | 3850 | 3950 | 4280 | 4350 | 4760 |

| D | 2750 | 2930 | 3210 | 3900 | 4600 |

| E | 500 | 500 | 500 | 500 | 500 |

| F | 2100 | 2280 | 2600 | 2950 | 3370 |