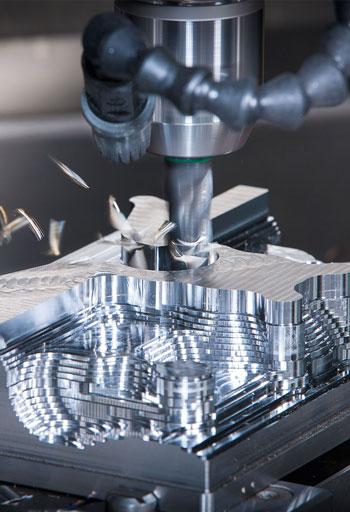

Coating Series Tools

FEATURES

Among other innovations brought by the HDP technology is a very versatile coating which can be widely used for various applications. HDP was developed to find a universal solution for the most traditional machining processes and to guarantee a constant yield and best performance of the tools.

Available with punches:

Trumpf, Amada, Finn Power, Euromac, Lvd, Rainer, Salvagnini, Tecnology, Wiedemann, Boschert, Tailift, Danobat, Durma, Ermaksan…

Coating is intact after 125.000 hits

nibbling 1mm stainless steel

The double coating is obtained by overlaying the traditional TICN with Movic self-lubricating coating.

MOVIC is a self-lubricating and anti-adhesive coating based on MoS2

(Molybdenum), which is produced by PVD sputtering Magnetron technology.

MOVIC has been developed in the aerospace to find alternatives to

traditional oils (eg oil, grease) when their use is not permitted and it has shown excellent tribological features that made it very interesting for a variety of new applications.

Available with punches:

Trumpf, Amada, Finn Power, Euromac, Lvd, Rainer, Salvagnini, Tecnology, Wiedemann, Boschert, Tailift, Danobat, Durma, Ermaksan…

SPECIFICATIONS

•Extraordinary toughness – this is the strong point of this coating and makes it versatile and particularly suitable for various applications

•Adhesion to the surface – the HDP technology makes it possible to obtain maximum adherence of the coating to the surface and makes the “tool/coating” combination become a whole.

•Microhardness – the very compact HDP Red layer, with a thickness of only 3 microns, gives a hardness which represents a solid barrier against wear and guarantees a unique performance.

•Low friction coefficient – this is another important characteristic, which becomes evident thanks to the glossy layer. The low friction coefficient has been made possible thanks to the HDP technology which makes the application of coatings almost “dropletfree” (residual macro – particles on the surface).If they are not removed, these droplets affect the surface roughness.

| Structure | MicroHardness (HV 0.05) | Friction coefficient (100 cr6) | Thickness (micron) | Deposition temperature (°C) | Max temperature (max°C) | Colour |

| Multilaver | 3.800 | 0.25 | 1-3 | 480 | 400 | RED |

•Self – lubricating single – phase coating based on MoS2.

•”Soft” coating with very low coefficient of friction (friction coefficient in dry air <0.05).

•Single – layer coating that can be combined with any hard coating.

•Functional Thickness of Coating <0.5 microns.

•Deposition temperature <150 ° C.

•Soft wear residues, lubricants (behavior Fail – safe: no abrasive particles from wear of the coating).

•Excellent running for rough surfaces. (Coating becomes smoother during the running in.)

•Positive transfer of lubricant film on the side in contact.

•can be easily re – covered without removal. If necessary the removal is easily achievable.

| Structure | MicroHardness (HV 0.05) | Friction coefficient (100 cr6) | Thickness (micron) | Deposition temperature (°C) | Max temperature (max°C) | Colour |

| Single layer | – | <0.1 | ۱ | <150 | – | GREY |