ES23 SERIES

CNC PUNCH PRESS MACHINE

FEATURES

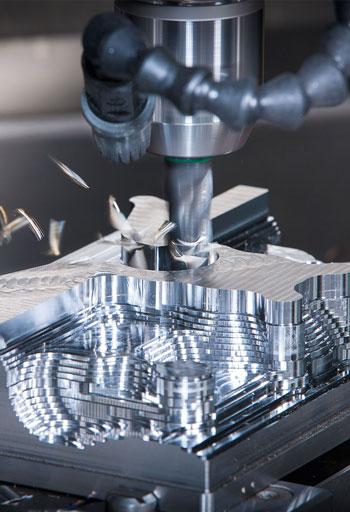

Tailift’s newly launched, ES23, AC Servo drive and numerical control technology. Featured with high speed, high precision, energy saving, and low noise. Equipped over-load protection, ES23 is an effective implement for thinner sheet metal. ES23 combined with processing abilities of punching, forming, roller cutting and tapping, an all-in-one machine. The integration assembly reduces floor space requirements effectively. Low average electricity consumption, energy-saving, eliminating the hydraulic . This ECO friendly product is the major milestone for Tailift’s R&D.

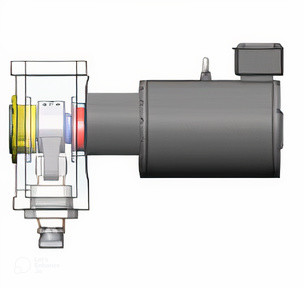

Ac Servo Electric System

ES23 equipped with high efficient AC Servo motor with single servo crank type punch head assembly without flywheel which results in high precision, Low noise and power consumption is only half of hydraulic models. No need of hydraulic oil and worry about environmental issues. High punching speed reduces the production time and ensure cost down.

Closed O Shape Frame Structure

High Rigidity & High Stability

The closed O shape frame structure is analyzed by the “Finite Element Analysis” software to simulate stress / strain conditions, enables the optimal structure design.

High Tensile Strength Steel Construction

The machine frame is welded by high tensile strength steel, which is subject to high tensile strength tests, normalization treatment and vibration stress relief so as to ensure the machine assembling accuracy.

SPECIFICATIONS

| Item | Unit | ES23 |

|---|---|---|

| Punch capacity | Ton | 30 |

| X traverse length | mm | 2490±10 |

| Y traverse length | mm | 1250±10 |

| Max sheet size | mm | 1250×4980 |

| Max sheet thickness | mm | 3 |

| Max blank weight | kgf | 110 |

| X traverse axis speed | m/min | 80 |

| Y traverse axis speed | m/min | 70 |

| Max traverse speed | m/min | 105 |

| Punch speed at | hist/min | 370 |

| 25 mm pitch | ||

| Nibbling speed | hits/min | 600 |

| Tooling type | Thick turret | |

| Max Punch diameter | mm | 88.9 |

| Number of tool stations | 34 | |

| Number of auto index | Number/Type | 2/(B Type) |

| Turret rotation | rpm | 30 |

| Auto index rotation | rpm | 100 |

| Ram stroke | mm | 0-31 |

| Model of working tables | Brush/ball | |

| No. of sheet clamps | pcs | 3 |

| Power supply | KVA | 40 |

| Compressed air pressure | bar | 6 |

| Oil tank volume | L | N/A |

| Machine dimension(L)x(W)x(H) | mm | 4690x5105x2110 |

| Net weight | kgf | 14000 |

| Size of separate control cabinet | mm | 2150x700x200 |

| CNC controller | FANUC 0iPD | |

| Number of controllable axes | 4+1 | |

| CMOS memory | KB | 512 |

| Serial Interface | RJ45/PCMCIA | |

| Punching accuracy | mm | ±0.1 |

Accessories

| Standard | Optional |

|---|---|

|

|

STATION ARRANGEMENT

ES23 SERIES