RH SERIES

CNC PUNCH PRESS MACHINE

FEATURES

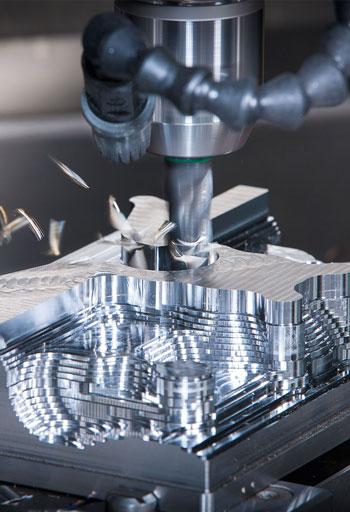

RH27 punch press machine is new generation Hydraulic series, inherited the features of high reliability and durability from series HP. With Germany H+L advanced servo-hydraulic system, its powerful punching performance is capable for punching big and thick sheets. Multi-functional for punching, forming, and tapping (option) significantly reduces stand-by time and increases material utilization. Furthermore, energy saving, high accuracy and high integrated assembly construction, effectively reduces maintenance cost.

Energy Saving System

Differential circuit system with High/Low voltage, minimize hydraulic unit, less than 30% hydraulic oil comparable typical hydraulic system. The compact size can reduce energy consumption and maintenance cost and save consumption cost.

SPECIFICATIONS

| Item | Unit | RH27 | RH27PLUS |

|---|---|---|---|

| Punch capacity | Ton | 30 | 30 |

| X traverse length | mm | 2490±10 | 2490±10 |

| Y traverse length | mm | 1525±10 | 1525±10 |

| Max sheet size | mm | 1525×4980 | 1525×4980 |

| Max sheet thickness | mm | 6.35 | 6.35 |

| Max blank weight | kg | 110 | 110 |

| X traverse axis speed | m/min | 80 | 80 |

| Y traverse axis speed | m/min | 70 | 70 |

| Max traverse speed | m/min | 105 | 105 |

| Punch speed at | hist/min | 250 | 280 |

| 25 mm pitch | |||

| Nibbling speed | hist/min | 360 | 600 |

| Tooling type | Thick turret | Thick turret | |

| Max Punch diameter | mm | 88.9 | 88.9 |

| Number of tool stations | 34 | 34 | |

| Number of auto index | Number/Type | 2/(B Type) | 2/(B Type) |

| Turret rotation | rpm | 30 | 30 |

| Auto index rotation | rpm | 50 | 50 |

| Ram stroke | mm | 0-31 | 0-31 |

| Model of working tables | Brush/ball | Brush/ball | |

| No.of sheet clamps | pcs | 3 | 3 |

| Power supply | KVA | 26 | 28 |

| Compressed air pressure | bar | 5 | 5 |

| Oil tank volume | L | 180 | 250 |

| Machine dimension(L)x(W)x(H) | mm | 5050x5200x5168 | 5050x5200x5168 |

| Net weight | kgf | 14000 | 14000 |

| Size of separate control cabinet | mm | 1100x535x1980 | 1100x535x1980 |

| CNC controller | FANUC OiPD | FANUC OiPD | |

| Number of controllable axes | 4+1 | 4+1 | |

| CMOS memory | KB | 512 | 512 |

| Serial Interface | RS232 / RJ45 / PCMCIA | RS232 / RJ45 / PCMCIA | |

| Punching accuracy | mm | ±0.1 | ±0.1 |

Accessories

| Standard | Optional |

|---|---|

|

|

STATION ARRANGEMENT

- The turret is transmitted through the worm and worm gear mechanism.

Two shafts are synchronously transmitted via a connecting rod for safe and dependable positioning. - The turret is designed with 34 stations, and accommodates various tool sizes from 1/2” to 3-1/4”. Changing tool size is available upon customer request.

- Each station can be fitted with various brand tools, such as Mate and Wilson.

- Designed with two circular track stations.

- Replaceable bushing easy to maintain.

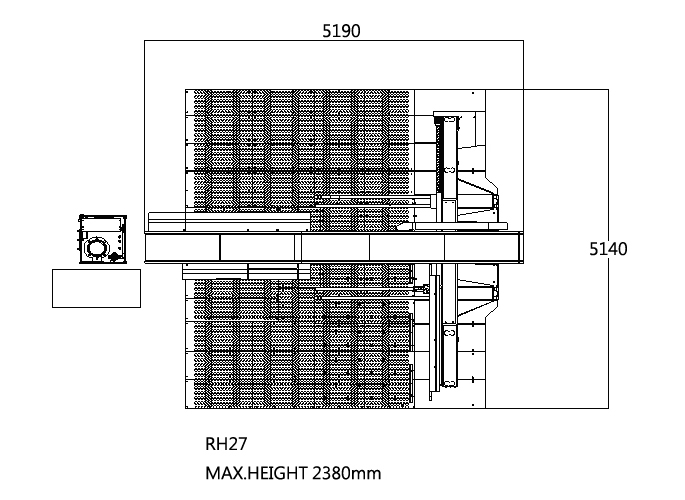

DIMENSIONS

CNC Punch Press Machine RH27 / RH27PLUS Series